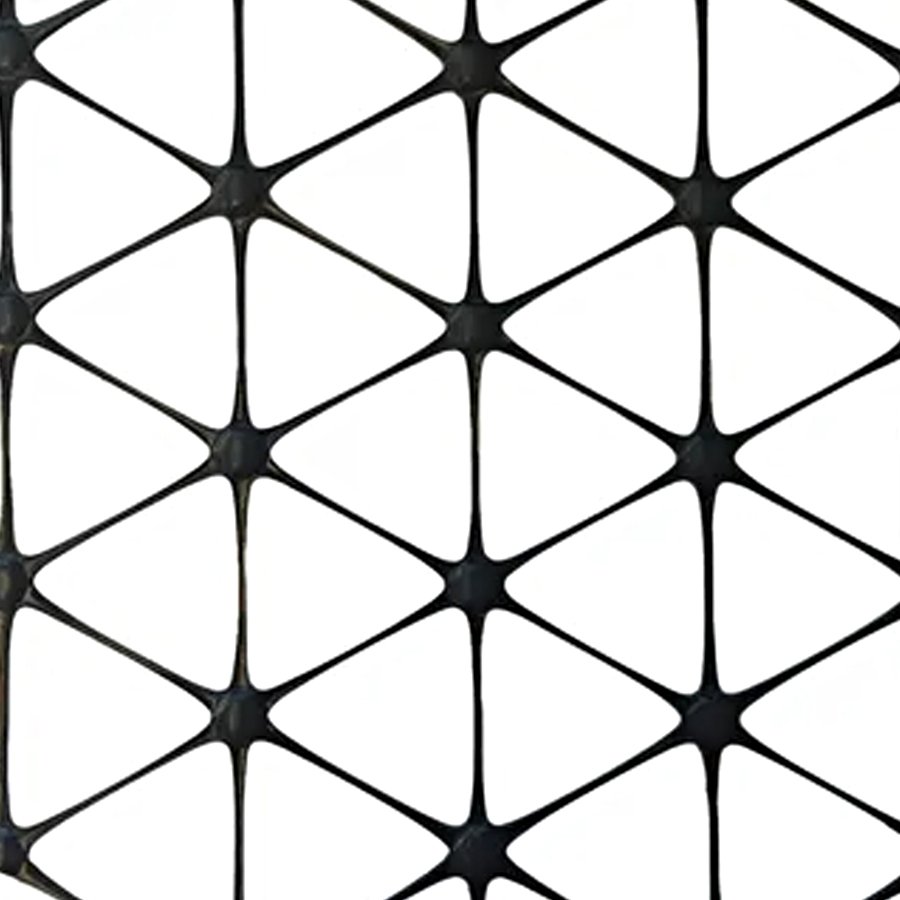

Triaxial geogrid is a new type of high-strength geosynthetics. Compared with traditional uniaxial or biaxial geogrids, triaxial geogrid adopts a three-way mesh structure, which can disperse the load more evenly and improve soil stability. This product is mainly used to enhance the bearing capacity of soft foundation, prevent roadbed settlement, and improve engineering durability. It is widely used in highways, railways, ports, water conservancy and other fields.

| Item | TestMethod | Unit | Standard |

| Polymer | - | PP | |

| RibMiddleDistance | - | mm | 35 |

| MinimumCarbonBlack | ASTMD4218 | % | 2 |

| RadialSecantStiffnessat2%Strain | ASTMD6637 | kN/m | 225 |

| Elongation | ASTMD6637 | % | 13 |

| JunctionEfficiency | GRIGG2 | % | 96 |

| ExperimentalConditions | Temperature:20℃ | ||

| RollWidth | - | m | 3.95 |

| RollLength | - | m | 50 |

Features:

More uniform force in three directions: The unique three-axis structure enables the soil to obtain better support in all directions and reduce deformation.

High tensile strength: Provides excellent tensile strength and bearing capacity, and enhances foundation stability.

Strong corrosion resistance: Made of polymer materials, it is acid-resistant, alkali-resistant, and aging-resistant, and suitable for various complex environments.

Good interlocking performance: It is more tightly combined with the filler, improves the overall strength of the foundation, and reduces settlement.

Convenient construction: Lightweight and easy to lay, improves construction efficiency, and reduces overall costs.

Application Areas:

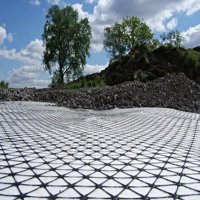

Highway and railway roadbed reinforcement: strengthen soft soil foundation, reduce settlement, and increase service life.

Airport runways and port terminals: enhance bearing capacity and prevent foundation damage.

Mining and dam projects: enhance slope stability and prevent landslides.

Wind power foundation and oil field projects: improve foundation stability in special scenarios.

Embankment and bank protection projects: prevent soil erosion and improve durability.

Landfill: prevent uneven foundation settlement and extend service life.

Customized Service:

Specification customization: triaxial geogrids of different sizes, thicknesses and strengths can be customized.

Material selection: HDPE, PP and other polymer materials can be selected to adapt to different engineering environments.

Color customization: conventional black, other colors can be customized as required.

UV-resistant and durable treatment: suitable for long-term outdoor use to increase product life.

Brand customization: support OEM production, and can customize Logo and packaging.

Production Scenario:

Automated production line: using advanced production equipment to ensure accurate product size and stable performance.

Strict quality inspection: each batch of products is tested for tensile strength, aging resistance, corrosion resistance, etc., in line with industry standards.

Green and environmentally friendly production: reducing carbon emissions and meeting the requirements of sustainable development.

Shipping Scenario:

Fast delivery: supporting national and international logistics distribution to ensure on-time delivery.

Professional packaging: coiled or folded packaging, moisture-proof, dust-proof, suitable for long-distance transportation.

Global export support: providing sea, air and land transportation, can be exported to multiple countries and regions.

Certification:

ISO 9001 Quality Management System Certification

CE Certification EU Market Compliance Certification

SGS Test Report Product Quality Test Certification

ASTM Standards Comply with the American Society for Testing and Materials

Environmental Testing Report Comply with environmental requirements

FAQ:

Q1: What is the main material of triaxial geogrid?

A1: Mainly made of high-density polyethylene (HDPE) or polypropylene (PP), it has excellent corrosion resistance and high strength.

Q2: What are the advantages of triaxial grid compared with biaxial grid?

A2: Triaxial grid can evenly distribute loads in more directions and improve the overall stability of the foundation, while biaxial grid mainly enhances strength in two directions.

Q3: How to install triaxial geogrid?

A3: First level the base, lay the geogrid and fix it, and then backfill and compact it. The specific construction method can be adjusted according to the project requirements.

Q4: What is the service life of the product?

A4: Usually up to 50 years or more, the specific life depends on environmental conditions and material properties.

Q5: Can you provide samples?

A5: Free samples can be provided, but the freight needs to be borne by the customer.

Triaxial Geogrid

Triaxial Geogrid

Triaxial geogrid is a new type of high-strength geosynthetics. Compared with traditional uniaxial or biaxial geogrids, triaxial geogrid adopts a three-way mesh structure, which can disperse the load more evenly and improve soil stability. This product is mainly used to enhance the bearing capacity of soft foundation, prevent roadbed settlement, and improve engineering durability. It is widely used in highways, railways, ports, water conservancy and other fields.