LDPE (Geomembrane) is a geomembrane made of low-density polyethylene (LDPE) and is widely used in civil engineering and environmental protection. Due to its unique physical properties, LDPE geomembrane has become an important material for anti-seepage, waterproofing, isolation and protection.

LDPE geomembrane material features:

Flexibility: LDPE geomembrane is softer than other high-density polyethylene (HDPE) geomembranes, so it is easy to handle during construction and can better adapt to irregular ground.

Corrosion resistance: LDPE geomembrane has strong chemical corrosion resistance and can resist erosion by a variety of chemicals such as acids, alkalis and salts.

Aging resistance: It has good UV resistance, but not as good as HDPE geomembrane, so it may be reduced under sunlight exposure. It is usually recommended to cover the geomembrane with a layer of soil or other covering materials to extend its service life.

Tensile strength and ductility: LDPE geomembrane has good tensile properties and can withstand certain mechanical stress.

LDPE geomembrane application areas:

Landfill: used for the bottom and side walls of landfills to prevent leakage and contamination of groundwater.

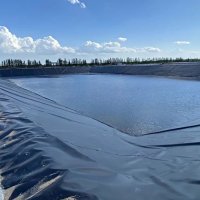

Water conservancy projects: such as anti-seepage projects such as pools, ponds, and channels to prevent water leakage.

Agriculture: used in greenhouses or irrigation systems to prevent soil moisture from evaporating or leaking.

Mining projects: used for anti-seepage isolation of mine deposits to prevent harmful substances from entering the environment.

Sewage treatment plants: used for anti-seepage isolation of sewage pools to prevent wastewater from seeping into the ground.

Specifications and performance indicators:

Thickness range: Common thicknesses range from 0.2mm to 2mm, and the specific choice depends on the needs of the application scenario.

Tensile strength: The tensile strength of LDPE geomembrane is generally between 10-20MPa, depending on the product specifications.

Permeability: LDPE geomembrane has excellent anti-seepage performance, and the water permeability coefficient is usually at the level of 10^-11cm/s.

| umber | Item | Index | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thickness mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

| 1 | Density g/cm3 | ≤0.939 | ||||||||

| 2 | Tensile breaking strength (vertical and horizontal) N/mm | ≥6 | ≥9 | ≥14 | ≥19 | ≥23 | ≥28 | ≥37 | ≥47 | ≥56 |

| 3 | Elongation at break (vertical and horizontal) % | ≥560 | ||||||||

| 4 | Right angle tear load (vertical and horizontal) N | ≥27 | ≥45 | ≥63 | ≥90 | ≥108 | ≥135 | ≥180 | ≥225 | ≥270 |

| 5 | Anti-puncture strength N | ≥52 | ≥84 | ≥135 | ≥175 | ≥220 | ≥260 | ≥350 | ≥435 | ≥525 |

| 6 | Carbon black content % | 2.0~3.0 | ||||||||

| 7 | Carbon black dispersibility | 10 data in the 3 not more than one, 4, 5 is not allowed | ||||||||

In stock:

1.0mm 1.5mm 2.0mm pond Geomembrane

1.0mm 1.5mm 2.0mm pond Geomembrane

LDPE (Geomembrane) is a geomembrane made of low-density polyethylene (LDPE) and is widely used in civil engineering and environmental protection. Due to its unique physical properties, LDPE geomembrane has become an important material for anti-seepage, waterproofing, isolation and protection.