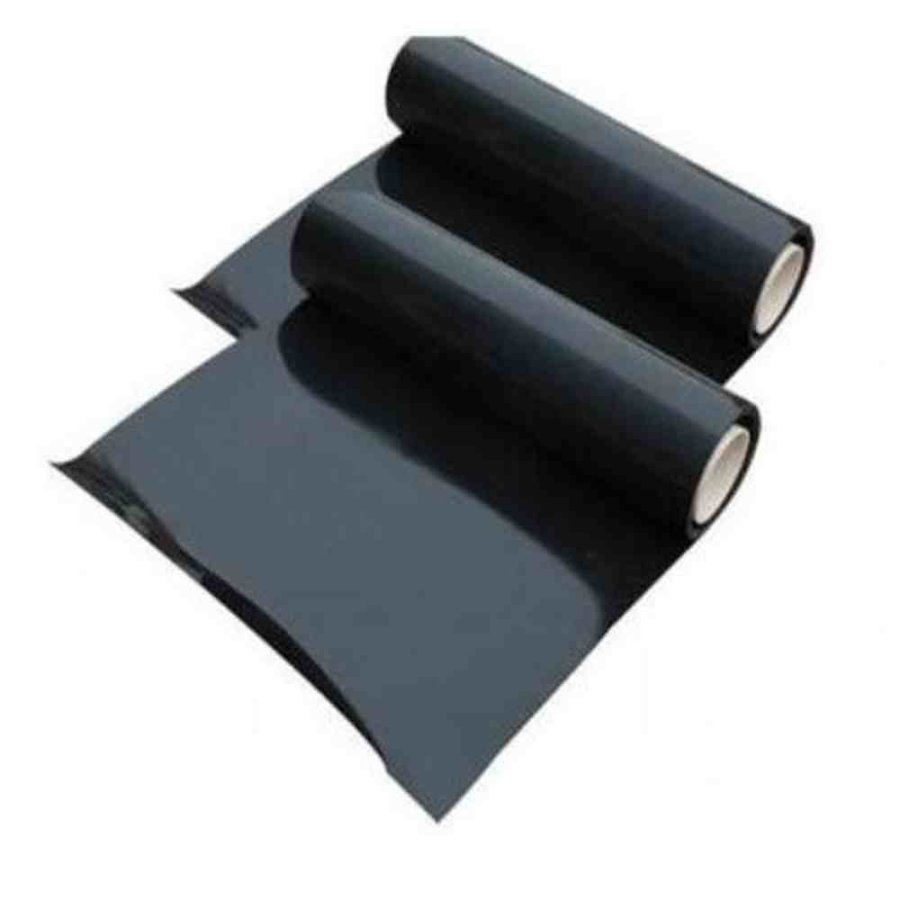

Black Fish Pond Protection 1.2/1.5MM ASTM standard geomembrane is a high-strength geosynthetic material specially used for water protection, such as fish ponds, artificial lakes and other water conservancy facilities. It uses high-density polyethylene with excellent anti-seepage and UV resistance, which can effectively prevent water leakage and prevent external pollutants from entering the water.

Fishpond geomembrane Features:

High-strength tensile performance: It has high tensile strength and elongation at break, and can withstand the mechanical pressure in the fish pond environment.

Corrosion resistance: Geomembrane has strong resistance to most chemicals, acids, alkalis and oils, so it is particularly suitable for environments immersed in water for a long time.

Anti-ultraviolet: Anti-UV agent is added to the surface of black geomembrane, which enhances its weather resistance in the sun and can effectively resist the erosion of ultraviolet rays.

Anti-seepage: The high-density structure of the geomembrane can effectively prevent water leakage, keep the water clean and the water level stable.

Low temperature resistance: It is suitable for low temperature environments and is not easy to become brittle or crack.

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH300 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 3.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties | ||||||

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 41 kN/m 82 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 375 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 960 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions | ||||||

■ Roll Width (m) | 7 | 7 | 7 | 7 | 7 | |

■ Roll Length (m) | 420 | 280 | 210 | 140 | 50 | |

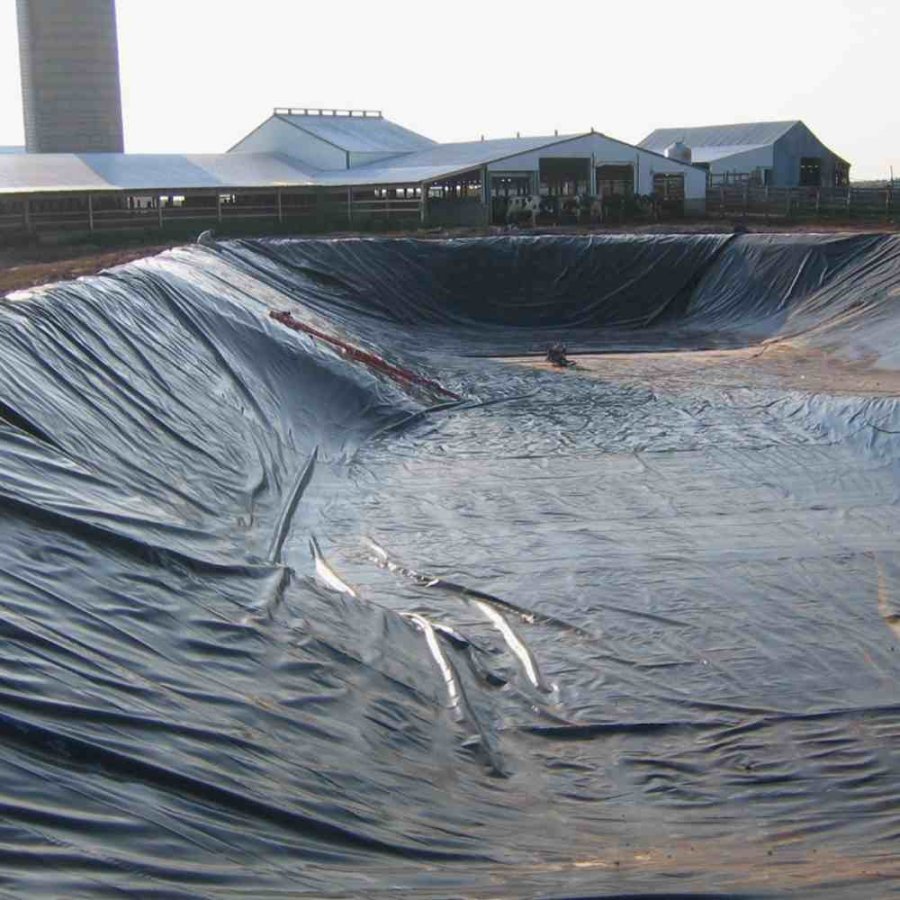

Fishpond geomembrane Application areas:

Fish pond protection: through effective anti-seepage, maintain the water quality of fish ponds and prevent harmful substances from entering.

Aquaculture: protect aquaculture water bodies and reduce external water pollution.

Ecological restoration: used for the construction of wetlands and artificial lakes to prevent soil erosion.

Agricultural irrigation: can be used for anti-seepage and reservoir construction to improve the stability of irrigation water sources.

Fishpond geomembrane Customized Service:

Specification customization: HDPE geomembrane liner with different heights, weld distances, sheet thicknesses, colors, etc. can be customized according to customer needs.

Connector customization: Connectors with different materials and specifications can be customized according to customer needs.

Packaging customization: Different packaging methods can be customized according to customer needs, such as roll packaging, pallet packaging, etc.

Production scenario:

Raw material preparation: Select high-quality HDPE raw materials and undergo strict quality inspection.

Sheet production: Process HDPE raw materials into sheets.

Ultrasonic welding: Use advanced ultrasonic welding equipment to weld the sheets into a three-dimensional mesh structure.

Quality inspection: Strict quality inspection of finished products to ensure that the products meet national standards and customer requirements.

Shipping scenario:

Logistics and transportation: Use professional logistics and transportation methods to ensure that products are delivered to customers safely and promptly.

On-site guidance: Provide professional on-site guidance services to assist customers in product laying and construction.

Certificates:

Product quality certification: Passed ISO9001 quality management system certification, CE certification, etc.

Product test report: Provide product test reports issued by authoritative organizations.

FAQ:

Q: How to choose the right geomembrane liner?

A: Consider impermeability: HDPE has the strongest impermeability and is suitable for highly polluted environments.

Consider flexibility: LLDPE and PVC are more suitable for complex terrains.

Chemical resistance: HDPE is acid and alkali resistant and suitable for the chemical industry.

UV resistance: Black HDPE has the best UV resistance.

Q: What is the construction process of geomembrane liner?

A: Foundation treatment: Clean the site to ensure that it is flat and free of sharp objects.

Laying the liner: Unfold according to design requirements to avoid wrinkles.

Welding/bonding: Use hot melt welding (HDPE/LLDPE) or adhesive bonding (PVC/EPDM).

Quality inspection: Conduct spark detection or air pressure testing to ensure no leakage.

Protective layer coverage: Lay geotextile or sand and gravel protective layer to prevent mechanical damage.

Q: How to detect the anti-seepage effect of geomembrane liner?

A: Visual inspection: Observe whether there are damage, holes or welding defects.

Spark detection (applicable to conductive geomembranes): detect tiny leaks.

Vacuum box detection: negative pressure test on welds.

Hydraulic pressure test (applicable to pools): inject water to observe leakage.

Q: How long is the service life of geomembrane liner?

A: HDPE liner: more than 50 years (under buried conditions).

Q: How to repair damaged geomembrane liner?

A: Small holes: use special patches + hot air welding or adhesives.

Large-scale damage: re-weld new membrane after cutting.

Weld crack: clean and re-weld.

Water conservancy project anti-seepage 0.5/0.75mm geomembrane manufacturer

Water conservancy project anti-seepage 0.5/0.75mm geomembrane manufacturer

High-density polyethylene (HDPE) geomembrane has gradually become the mainstream anti-seepage material due to its excellent anti-seepage performance, chemical stability and weather resistance. It has specifications of 0.5mm and 0.75mm thickness and is more widely used in small and medium-sized water conservancy projects and agricultural irrigation systems.

Black fish pond protection 1.2/1.5mm ASTM standard geomembrane

Black fish pond protection 1.2/1.5mm ASTM standard geomembrane

Black Fish Pond Protection 1.2/1.5MM ASTM standard geomembrane is a high-strength geosynthetic material specially used for water protection, such as fish ponds, artificial lakes and other water conservancy facilities. It uses high-density polyethylene with excellent anti-seepage and UV resistance, which can effectively prevent water leakage and prevent external pollutants from entering the water.

Pond water seepage prevention 1.0mm geomembrane liner

Pond water seepage prevention 1.0mm geomembrane liner

Geomembrane liner waterproof and anti-seepage material has high anti-seepage performance, chemical corrosion resistance, aging resistance and mechanical strength. It is widely used in anti-seepage projects such as landfills, reservoirs, artificial lakes, sewage treatment pools, and mine tailings ponds.

HDPE Geomembrane

HDPE Geomembrane

HDPE geomembrane (high-density polyethylene geomembrane) is a waterproof and anti-seepage material made by blowing or calendering process. It has excellent anti-seepage performance, chemical corrosion resistance, aging resistance and mechanical strength, and is widely used in anti-seepage projects such as landfills, reservoirs, artificial lakes, sewage treatment pools, and mine tailings ponds.