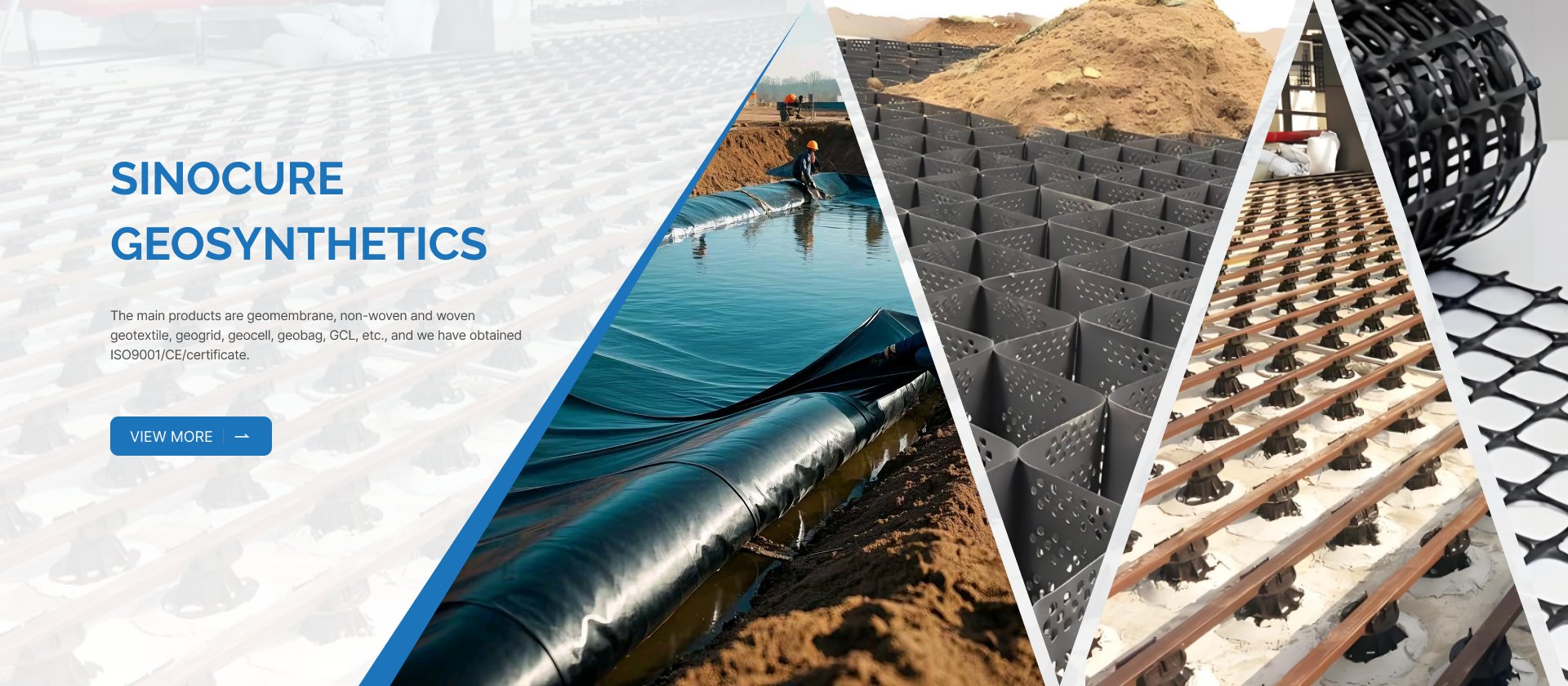

Sinocure Geosynyhetics Co, Ltd., Ltd. is a geosynthetics manufacturer from China, with a total of fifteen production lines of geomembranes, geogrids, geocells, geotextiles, geobags, drainage cages, and floor supports, etc. Our products have been exported to 36 countries and regions, such as Vietnam, Malaysia, Indonesia, the United Arab Emirates, Saudi Arabia, Peru, and Argentina. We have won favorable comments from domestic and foreign customers for our high quality and excellent service.

Benefit from our global presence and deep understanding of local market needs in over 36 countries.